Industries

Wiring Harnesses for your industry

We build wiring harnesses for industries that demand performance. From mining to military, our solutions are built tough, tested hard, and made to fit. Explore the sectors we support across Australia and beyond.

Equipment Rebuilders

Specialised Vehicles

Military & Defense

Keeping you operational

From our state-of-the-art factory here in Brisbane, we provide exceptional, on-time service. From custom made wiring harnesses, to OEM replacements and alternatives, we can help.

Our priority is keeping your machines running and helping you maintain productivity.

If you haven’t already, it’s time to discover the WHA difference.

Ask us for a quoteOrganised, efficient, reliable

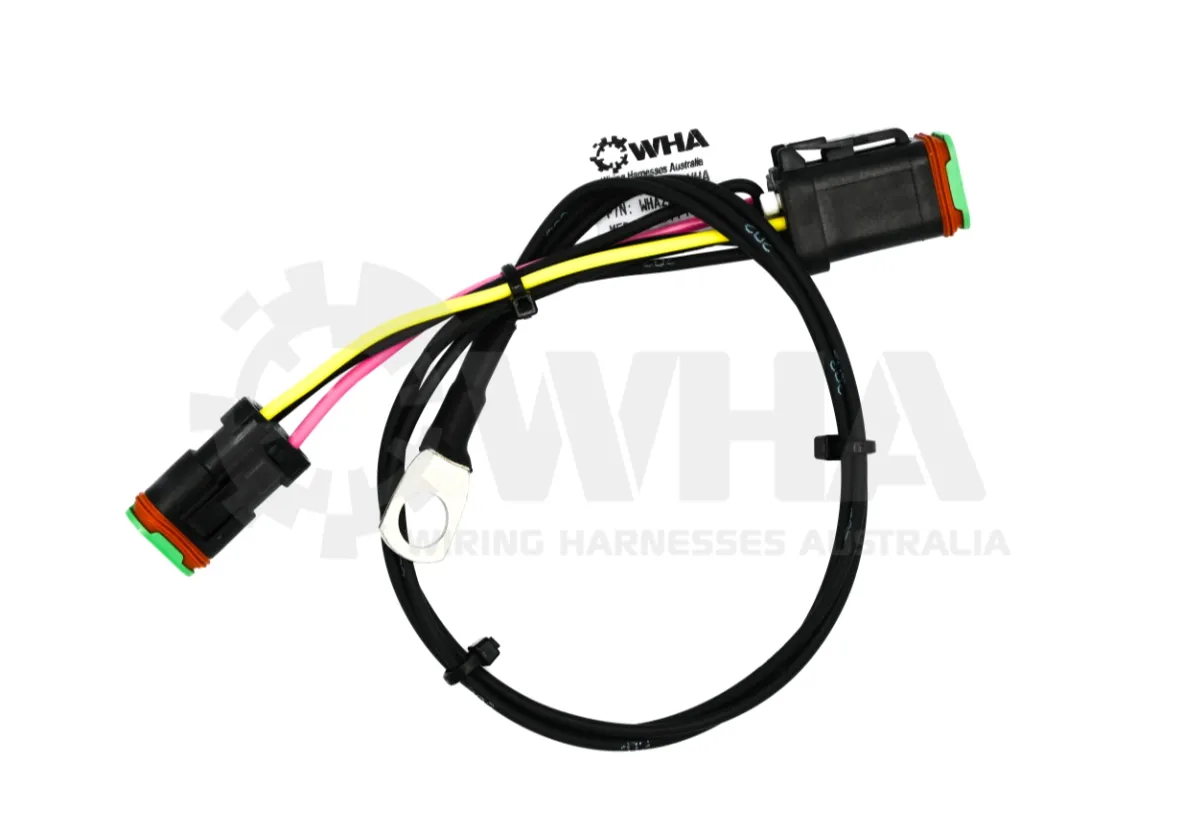

At Wiring Harnesses Australia, we know how important it is to keep your automotive wiring as organised as possible. Confusion can lead to mistakes. Mistakes can lead to delays and injuries. For this reason, we have devised foolproof strategies to ensure your wiring plans are clear and easy to communicate.

- Wire printing, connector labels and trace colours to ensure cables can be easily identified

- For easy identification and ordering, all harnesses are labelled with a part number label with manufacture and test date

- Colour schematic drawings of harnesses, including part numbers for all components (where required and requested)

We also provide a range of aftermarket systems for vehicle fleets including complete packages covering lighting, communications and safety systems. These packages include all fastenings, fixings and hardware for installation.